To prevent a initiation of karst-suffusion processes in the base of exclusive apartment house a cementation of Perkhurovsky karst limestones stratum from the bases of diaphragm walls panels and deep foundations to the roof of lying bellow waterproof marly-clays was made after the completion of diaphragm walls and deep foundations erection through the metal pipes with 114 mm diameter had been laid during their construction.

Drilling workings was done applying the rig HBM15 and the cement grout injection under the pressure 2.5 bar with the pump PH125C. Initially the grout with water-to-cement ratio W/C = 0.8 of 400 l volume has being injected and then in case of pressure drop during 10 minutes – with W/C = 0.5-0.6 – to the full. Sodium silicate was added into grout to decrease its consumption. Thus, the watertight curtain in the diaphragm walls base around the building zero cycle was practically executed as well as cementing consolidation of eroded Perkhurovsky limestones, the caverns under the deep foundations and diaphragm walls were eliminated.

Ground excavation was carried out under the protection of one-level temporary metal support which included four knee braces made of 530 mm diameter pipes, one intermediate bunton made of 820 mm diameter pipe and the belt made of the coupled flange beams №40 Б1.

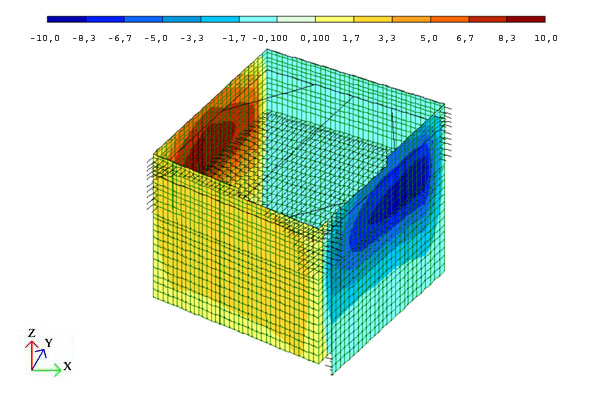

Small dimensions of enclosure and excavation pit depth have determined strongly pronounced spatial character of diaphragm walls operation that was confirmed by appropriate calculations.

To reduce the 14-storey building-tower zero cycle constructional elements settlement difference caused by irregularity of loading and complexity of geological conditions the deep foundations and diaphragm walls were jointed by the foundation slab of 60 cm thickness. The slab had the thickness up to 78 cm over the deep foundations.

The diaphragm walls were connected to the foundation slab by means of ~12 cm deep grooves and two tiers of bar glued anchor stays HILTY (HIT-HY 150) in diameter 25 A-III with a 400 mm step.

The foundation slab waterproofing was executed applying the bentonite mats Voltex, connection joints of the foundation slab with deep foundations and diaphragm walls are additionally condensed with the help of bentonite-rubber hydro-gasket “Red stop”.

As the diaphragm walls were constructed under the special technology of the company "SOLETANCHE BACHY" applying joint condensing between the panels with the waterproofing tapes of "Waterstop" type, the walls waterproofing was not envisaged. Insufficient local water penetration through the wall defects were removed by the caulk using the compositions with noncontracting or self-stressing cement and along the panel body – by the injection of polymeric pitch “CARBOSTOP W” (“CARBO Add X (Y)”) or “CARBOPUR WFA 16 – BEVEDAN” by the firm CarboTech Fosroc Gmbh. production.

The in-situ reinforced concrete floor-slabs with the thickness of 30 cm (under the pool – of 40 cm thick) are made plane and girderless and supported by the diaphragm walls with grooves of about 16 cm deep.

The structures of the zero cycle were designed using the 3D-calculation scheme with consideration of loading due to 14-storey aboveground part of building.

Publications…

Patents…

Drawings catalogue…